High-Resolution Imaging with the Highest Quality Ink

Giant Printing Produces Brilliant & Durable Trade Show Displays

Giant Printing uses a 2-step print process that allows for greater control of color, sharpness, and detail when it comes to your trade show displays and products.

At Giant Printing, we don’t do Direct to Fabric printing. It is the cheapest and lowest quality in the marketplace. This substandard technology requires printing onto a “coated” or “treated” fabric. Direct to Fabric printing results in a very stiff product, causing uncontrollable wrinkles, poor image quality, less detail, and inaccurate color.

Giant Printing’s Printing Process

In this video, we start by printing an image in reverse onto transfer paper. We then transfer the image from the paper using an offline transfer machine. After the image has been transferred it’s ready for sewing.

2-Step Printing Process

We do NOT print on the fabric. We use a 2-step process that requires us to print at a very high resolution with high-quality inks directly onto paper.

We then transfer the image using an offline heat press. When heat-activated, our inks penetrate the fibers of the fabric, infusing or embedding your image. This type of printing process is permanent because the image becomes part of the material.

The heat transfer will not peel or crack and lasts for many years. The final product has great detail, an elegant look, a soft feel, and brilliant color reproduction.

One of the many benefits to our 2-step process is you get a product so durable you can clean it in your washing machine.

Comparison of Our Printing Process to Our Competitors

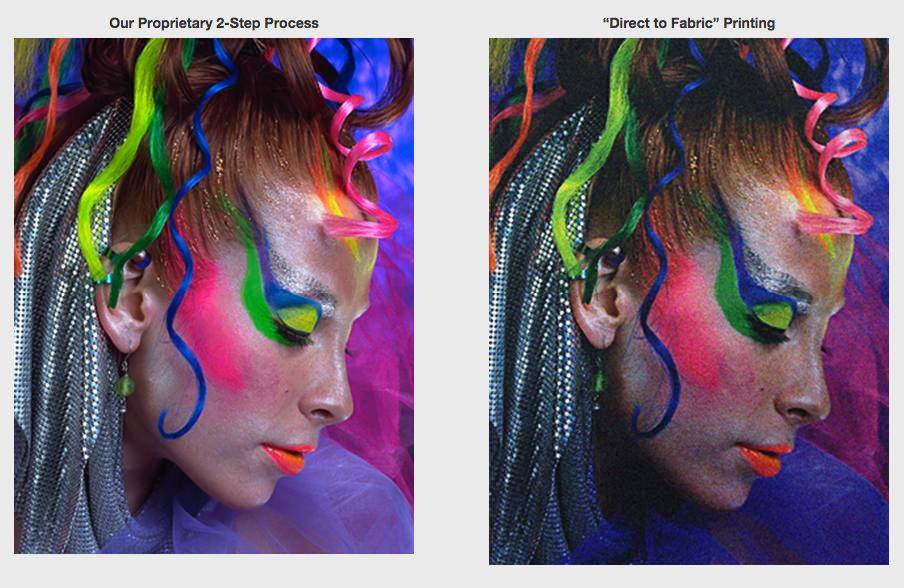

Comparing our unique printing process to our competitors is like comparing Hi-Def Digital TV to an old Analog Broadcast. Our 2-step printing process allows for greater control of color, sharpness, and detail.

See the comparison in the 2 images below.

Advantages of Our Printing Process.

- We offer the highest print quality for printing on fabric/textiles

- Our printed textiles are very durable and most can be laundered without any concern of them losing their appeal

- Full-Color Process – no difference in cost between 1,2,3,4 color designs

- We can print larger print sizes than a litho press (or screen press)

- “The proof” is an actual output of your file on your fabric of choice

- Photographic quality image capability

- Very cost-effective

- More elegant look and feel than vinyl or plastic

- Portability – can easily be rolled/shipped

- Storage – most textiles do not wrinkle

- Easy to fit on your displays, stands, frames, & structures

- Lightweight – Saves on shipping charges

Look Professional Every Time

Photo realistic fabric backdrops that really stand out

Clean Installation

Grommet-Free design hides unsightly hooks and ropes so that customers focus on your products, not your installation

Photo Realistic

Proprietary printing process and specialty inks create a more vibrant display, with more depth of color at a much higher resolution

Reusable Display

Machine Washable with American-made fabrics and inks won’t run, fade, or wash off to ensure a lifetime of quality